· Editor · 8 min read

What is Car PinchWeld? The 101 Ultimate Guide

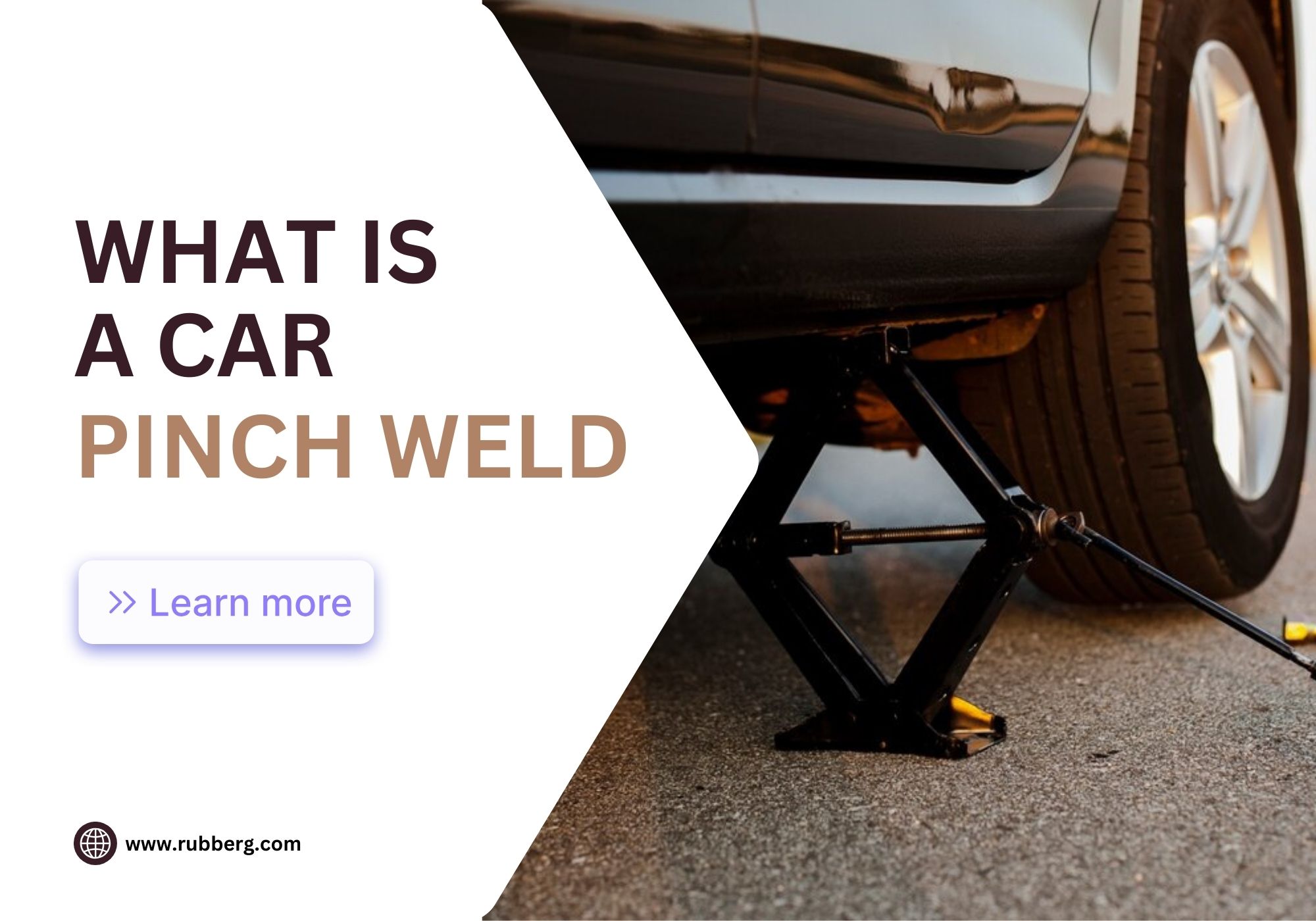

Car pinch weld is an integral part of the vehicle structure When lifting it holds the weight of the vehicle Learn more about it here.

Who doesn’t like cars? Yes, that’s why the automotive industry is so prevalent in every corner of the world. Over many years, this industry has developed a wide range of vehicles with different capacity levels. With the help of technology, they improved vehicle structural integrity year after year. Car pinch weld is a crucial part of a vehicle that sticks together all the used metal sheets. It provides you with a jackpot for easy lifting.

You may wonder what exactly this car pinch weld is. Many of us may already know about pinch weld, but many may not. Besides, some may already know about a car pinch weld but cannot fully describe it. For all such readers, we have prepared this article today. After reading this article, we hope you will know the importance of car pinch weld. You will also learn how to maintain it and ensure the long life of your vehicle. So, no more delay, let’s get started.

Although a car pinch weld is not a term that immediately springs to mind for many, it is like the unsung hero of your vehicle’s structure. The high-quality pinch weld provides smooth functioning and a safe ride. On the other hand, old or damaged pinch welds result in potential hazards on the road.

What Is Car Pinch Weld?

A typical automobile has various metallic structural components, such as a body, chassis, or frame. These are separate metal components that vary based on different vehicle structures. Now, here comes the answer to the question. A car pinch weld is where all these components come and join together. The process involves heat, pressure, and time.

You may wonder why it is called car pinch weld. The answer is simple. The process applies high pressure on these metal sheets when welding them together. This welding is widely popular as spot welding. In easy words, you can imagine two sheets of paper between your thumb and forefinger.

There are some reasons for making Pinch welds on cars. One of the most important reasons is supporting lifting the vehicles. You may need to lift your car a bit during repair or servicing. In those cases, you can place your jack on these pich weld areas to raise the car smoothly. Car pinch weld balances the vehicle’s weight and protects your vehicle’s structure.

Moreover, you should also know that a car pinch weld is one of the strongest welds. During the process, the high pressure and high voltage provide high heat. This extreme temperature allows metal sheets to melt and mix between the components. Therefore, it is famous as one of the most potent welds in the world.

Pros

- The car pinch weld method is relatively cheaper. This method is also more effective than plug welding.

- You can use this welding method to attach two metal sheets permanently or temporarily.

- Car pinch weld is the best place to put a jack.

- Mild damage of a car pinch weld is repairable.

- Pinch weld is particularly useful for heavy-duty applications.

Cons

- All metals are not suitable for pinch weld except steel.

- Car pinch weld defects may create problems like cracked frames or leaked fuel tanks.

Factors Affecting Spot Welding (Pinch Weld on Car)

Spot welding or pinch welding is prevalent in vehicle manufacturing and repair. You already know that this process combines heat, pressure, and time. The result we find is a robust connection and surprising strength. Usually, the automobile industry uses high-strength steel in the manufacturing process. Do you know why? Because pinch welding on these materials provides more stability than plug welding. However, three primary factors affect pinch weld on cars.

Material thickness and electrical conductivity

You already know what spot welding is. Now, let’s explore how it works. The engineers set the spot welder type based on the sheet metal thickness and its type. These factors also determine how much current should be applied for welding. However, each metal comes with different thermal conductivity and electrical resistance. In addition, the metal thickness determines the size of the copper alloy electrode.

Pressure for the lap weld joint application

After the material, the following vital parameter to consider is the pressure. It is the pressure the spot welding process applies to the base metal. While using the pressure, the process passes a high-voltage electric current through the weld joint. The engineers typically pay attention to this stage to avoid gaps between the metal sheets. The high-voltage electricity creates extreme heat. Consecutively, it establishes the weld pool.

Welding and cool-down time

The final parameter is time. We all know that time is crucial in our lives. It determines the quality of our jobs. The same goes for spot welding or pinch welding. The time may vary based on the thickness or properties of the base metal.

Types Of Car Pinch Weld

You may be thinking that, by seeing the picture above, pinch welds may have just one type. Not actually. It depends on the type of car’s chassis. In this case, the car’s lower chassis type mainly depends on the type and function of the vehicle. Therefore, there are different types of car pinch weld, too. Let’s have a look at these categories.

L shaped

This Pinch Weld Car is the most common, which can be found in many vehicles near you. You can find an L-shaped pinch weld under the car. Making this type of weld is pretty straightforward. First, you grab two sheets of metal. One of them needs to be shaped like an L. It is like bending at a 90-degree angle while the other sheets should be flat.

Flat shaped

Welders assemble this joint using a method similar to that used for a regular car pinch weld. In this method, they connect two flat metal sheets that run side by side.

Z shaped

The Z-shaped pinch weld is kind of like two L-shaped ones teaming up. Imagine a diagonal metal sheet with an L-shaped joint at the top and another at the bottom. You’ll spot this buddy at the front of your car, making the frame for your windshield and windows.

Common Problems of a Car Pinch Weld

You know your car’s pinch welds are crucial to maintaining it. But they’re not invincible. They can encounter issues like rust, dents, or even weld failure. In this section, let’s explore some everyday troubles pinch welds can encounter.

Corrosion and Rust

Picture this: your car’s pinch welds are often exposed to nastiness. For example, mud, water, and grime are noteworthy. Over time, this can lead to rust and corrosion eating away at them. Not cool, right? Rust can weaken their strength. It potentially messes with your car’s structural integrity.

Dent

Sometimes, accidents happen. Your car’s lower side might meet a curb or a rogue rock, and then that goes down. Then, your pinch welds can take a hit and end up with dents. These dings can affect how they distribute weight. If you leave it unattended, it could lead to more significant problems.

Breakage

In some not-so-awesome cases, the weld themselves can call it quits, like giving up. Maybe it’s from your years of heavy lifting or wear and tear. If the weld breaks, it’s not great for your car’s overall strength.

Weld failure

In some cases, the welds might fail due to wear and tear. This undermines the vehicle’s overall integrity and can create dangerous situations. When welds fail, they are like weak links in the chain, and your car’s structural integrity could be compromised.

How Do You Prevent Pinch Weld Damage

Regarding your car’s pinch weld problems, prevention is often the name of the game. To avoid the abovementioned issues, it’s important to take proactive steps. Here’s how you can keep’em in tip-top shape:

Using The Right Quick Jack Pinch Weld Block Or Pinch Weld Puck

These nifty little tools are like bodyguards for your pinch welds. They fit snugly onto your jack and provide a cushioned, secure grip on the pinch weld. So when you’re jacking up your car for maintenance, these buddies ensure your pinch welds stay dent-free.

Using An Appropriate U-Channel Jack Stand

Jack stands are strong, silent, and keep your car safely elevated. When choosing a jack stand, ensure it’s designed with a U-channel that perfectly cradles your pinch welds. This way, you’re not risking damage when your car is perched up.

Pinch Weld Rubber Seal

Think of this as your pinch weld’s raincoat. A pinch weld rubber seal adds a layer of protection between your car’s underbelly and the elements. It shields against water, salt, and grime, which can all lead to corrosion and rust.

Pinch Weld Frame Rail Guard

Consider a frame rail guard if you want to go the extra mile in safeguarding your pinch welds. It is like a shi9eld for your undercarriage, protecting it from road debris, bumps, and scraps. It also protects your pinch weld when lifting with an unprotected jack stand.

Final Thought

Alright, folks, it’s time to wrap this up. We’ve journeyed through the world of pinch welds. In addition, we learned about their different shapes and their everyday problems. And most importantly, we learned how to maintain them from various issues.

Remember, pinch welds are among your vehicle’s most essential parts. So, don’t forget them when you’re working on your car or just giving it a once-over. Use the proper pinch weld rubber seal to protect them. That way, you can ensure your car’s structural strength and safety.